Our resilient, high-strength steels, our technological leadership in state-of-the-art hot and cold forming processes and our expertise in welding technology support the lightweight construction and sustainability efforts of the commercial vehicle and work machinery industry. Manufacturers of commercial vehicles and yellow goods, construction, mining and agricultural machinery, rely on the quality of the customized products in the voestalpine portfolio:

- Material and manufacturing processes for lightweight solutions

- Reliable solutions for chassis

- bodywork

- Agricultural machinery, construction machinery, lifting equipment and

- Load-resistant welded joints.

Materials for lightweight construction

We meet the high demands of the commercial vehicle and work machinery industry with innovative material solutions. To ensure optimum formability even with high-strength materials, we have developed a wide range of high-strength hot-rolled steels.

We have optimized "hot-rolled drive" steels for the most demanding forming processes. The micro-alloyed steels are characterized by a very fine-grained and largely single-phase microstructure. They are ideal for complex components with sheet thicknesses from 2 mm, for bending and deep-drawing operations and have very good edge formability. They enable the economical cold forming of chassis and seat components, structural and reinforcement components, occupant protection systems and much more. Our complex-phase steels can be used to implement complex forming steps.

Our range of lightweight materials also includes

- the high-strength and weldable aldur® fine-grain steels with excellent toughness at low temperatures, e.g. for highly stressed, welded structures in crane and vehicle construction and in mining machinery, as well as

- the wear-resistant premium steel durostat®, a steel with maximum hardness for use under enormous mechanical stress, intensive loads and heavy abrasion, e.g. for use in tipping skips, scrap containers, truck bodies, excavators and snow ploughs.

For the most demanding applications in vehicle construction, our voestalpine Wire Austria manufactures cold heading wire in diameters from 0.5 to 49 mm, the ideal material for cold heading and cold extrusion. Its rolling bearing steel wire is optimized for the production of ball, roller and needle bearings.

Our High Performance Metals Division supplies special steels for vehicle components that need to be particularly heat-resistant, tough and corrosion-resistant. With our valve steels, we also offer a product that is resistant to the diverse stresses in combustion engines.

Lightweight construction production

We use a wide range of production solutions for lightweight construction in commercial vehicles and yellow goods, from welded blanks and seamless tubes to high-strength hollow sections with customer-specific cross-sections. The wide range of products we offer for the construction of agricultural and construction machinery, buses, cranes and forklifts is supported by our global companies with their material and forming expertise.

-

The endurance® family from voestalpine Krems offers, for example, cold-formed hollow sections in different variants to meet specific requirements. Shaped tubes and hollow sections are continuously formed from strip to the desired cross-section using the latest forming technologies.

The pre-material of our voestalpine steel guarantees compliance with tight tolerances, e.g. for strip thickness and chemical composition. This enables us to achieve optimum conditions for maximum dimensional accuracy with regard to the cross-section and straightness of our products. The surfaces of the cold-formed components also save the user time-consuming post-processing steps before painting.

-

"ToughTubes" are our thermomechanically rolled seamless steel tubes. In order to meet our customers' requirements for high-strength seamless steel tubes, voestalpine Tubulars technicians have developed a new technology for the production of excellent cold-formable tubes that are also outstandingly weldable, combine high strength with excellent toughness and have improved surface quality and an extremely fine-grained microstructure.

-

The seamless hot-rolled hollow sections from voestalpine Tubulars offer numerous advantages thanks to their excellent product properties. They are durable, resistant, precise and versatile. Their high strength combined with low weight and improved corrosion resistance make them a preferred choice for demanding construction projects.

-

Laser-welded blanks with non-linear weld seams and integrated variable thickness variation, including ultra-high-strength versions, create individual component properties and thus provide a basis for vehicle-specific weight reduction. We develop and manufacture them at voestalpine Automotive Components Linz in customer-specific designs - even in large series.

-

By combining our experience in tube and sheet metal forming with our joining know-how, we open up new resources for our customers. voestalpine Rotec and voestalpine Automotive Components Linz offer the highest level of development expertise in this area. Thanks to the wide range of systems for tube and sheet metal forming and processing, we can develop optimal solutions together with our customers. We use a wide variety of joining processes and offer surface treatment according to customer requirements.

We have a broad international base for implementing innovative solutions for commercial vehicle and yellow goods manufacturers and their suppliers. Our voestalpine Roll Forming Corporation in the USA, with its high level of expertise in customized roll forming, bending, welding and cutting of components, structural tubes and assemblies, is available to meet the challenging demands of our customers in North America.

Further material and production offers

-

For the demanding applications in the commercial vehicle and yellow goods sectors, our cold-rolled flat steel ensures the tightest thickness tolerances combined with the best surface appearance. It is therefore suitable for a wide range of applications.

-

We produce high-quality wire solutions as primary material for a wide range of applications in commercial vehicles. Wires for this industry must have a highly uniform microstructure and a fine grain and be free from cracks and uneven accumulations of alloying elements. Their countless applications include, for example

- Axle, vibration damping and clutch springs in the chassis,

- roller and ball bearings in engines, chassis and gearboxes, as well as

- steel cord for tires.

-

As we manufacture our slit strip on state-of-the-art slitting lines, we can meet the highest customer requirements. Compliance with the tightest tolerances forms the basis for efficient vehicle construction.

-

The high demands in the commercial vehicle sector are reflected in the requirements for tools and tool steels. High-strength steels for lightweight construction, for example, require suitable tools. The voestalpine High Performance Metals Division is the world market leader in this field. Depending on the application, our high-quality tool steel offers high tensile strength, toughness, working hardness, wear resistance and corrosion resistance. The high-speed steels from our production have proven themselves many times over in the metalworking industries, including the manufacture of commercial vehicles and yellow goods.

Chassis

Whether used in transportation and construction, in warehouses or in agriculture - commercial vehicles and yellow goods are subject to the highest stresses. That is why we offer their manufacturers and their suppliers components and services that support long-term use. These include longitudinal and cross members as well as tube and profile solutions for a wide range of applications.

-

Highly resilient chassis form the basis for the stability, safety, load-bearing capacity and performance of vehicles and construction machinery. Our beams help to meet these requirements. They support the drive, body and payload and stabilize against external forces. voestalpine Roll Forming Corp. also manufactures side members for Class 6, 7 and 8 trucks, which, for example, accompany the logistics trends in Central and North America.

We offer our customers ready-to-install solutions consisting of side members with tapered, pressed or open tapered ends. We supply our complete side members with all perforations and the desired chassis number, sandblasted and KTL-coated.

-

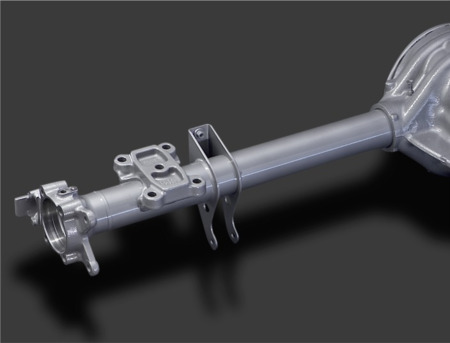

With our extensive material and manufacturing expertise, we produce axle support tubes, for example, fully automatically using the radial forging process. This also includes sandblasting, internal and external mechanical processing in a center lathe as well as the final inspection and signature using magnetic particle testing.

In a closed process chain, our voestalpine Rotec manufactures forged parts for the rear axle area of commercial vehicles. The required tube is cold drawn and cut to length before being further processed in a forging center. Our sites have state-of-the-art production facilities for further processing steps at the customer's request.

As an integrated supplier of high-performance drop forgings, the High Performance Metals Division's range extends from its own melting material to heat-treated forgings. Typical products are parts for commercial vehicle suspensions, such as safety components for the front axles of heavy goods vehicles.

-

The use of our high-strength tube solutions and hollow profiles not only guarantees a high level of stability for tools and machines, but also supports the lightweight construction trend in the industry. For use both in functional areas and as safety-relevant components, we develop components according to customer requirements and profile them ready for installation.

Seamless precision steel tubes are used wherever high dimensional accuracy, smooth surfaces and increased strength values are required. Our welded and cold-drawn precision tubes are produced by cold-forming stretch-reduced or HF-welded pre-tubes. Among other things, voestalpine Rotec produces seamless tubes for

- Transmission axles and drive shafts

- Fuel injection tubes

- Piston pins and ball cages

- Steering rods and power steering systems

- Hydraulic, pneumatic and telescopic cylinders

Seamless hot-rolled steel tubes from voestalpine Tubulars are also used as products or product components in the commercial vehicle and automotive industries. Depending on customer requirements, these are produced in round (Industrial Pipes) or square form (VTS®-edgeTubes hollow sections). The industrial pipes can also be supplied to the customer with "thought tube" technology.

Application examples:

Industrial Pipes

- Axles for trailers and light commercial vehicles

- Pulleys

- Damping elements and vibration dampers

- Drive train solutions

VTS -edgeTubes ®

- Axles for trailers

- Axles for trucks

- Base beams for trailers

-

We use the expertise of our cold forming sites to develop and produce ready-to-install assemblies and safety/impact protection components made of steel and aluminum. Using state-of-the-art equipment, we process a wide range of materials into cross members, brackets, reinforcements, etc.

In France, our voestalpine profilafroid/S.A.P. manufactures components such as cross members, underride bumpers, trailer edges and side wheel guards in addition to mechanisms for positioning and closing trailers.

-

The development of drive solutions for commercial vehicles, especially trucks and buses, is increasingly focusing on the use of environmentally friendly energy. In addition to electric variants, manufacturers are focusing on gas-powered vehicle variants. With our cryogenic nickel sheets, we offer the basis for the construction of ethylene, LPG or LNG tanks. Our state-of-the-art production facilities enable us to manufacture the corresponding steel grades, e.g. nickel steels.

For mobile tank systems with highly compressed hydrogen, we supply tested pressure vessels, pipes and connections made of hydrogen pressure-safe stainless steels, for special requirements also in wire-reinforced construction. Thanks to its extensive experience with critical tube components, the voestalpine Rotec Group also has the know-how to produce high-quality fuel, water and coolant tubes.

Car body

As with passenger cars, large outer skin parts are the eye-catcher of commercial vehicles. They are therefore one of the most demanding segments of our product range. We manufacture components from sheet steel or aluminum on fully automated press lines with tool sizes of up to 5 m.

For commercial vehicles and yellow goods, especially in the highly stressed construction and conveyor segment as well as in agriculture, special attention is paid to safety requirements. Our cab components, also as complete assemblies, meet the highest safety standards and are developed by us on a customer-specific basis.

Structure and outer skin

As the basis for container, bulk goods or passenger transportation, the variety of applications for commercial vehicles is almost unlimited. Our galvanized steel strip offers maximum corrosion protection for all types of use.

-

Cold-formed profiles, e.g. high-strength steel tubes from our voestalpine Profiles (China) Co. Ltd. form the support structures of electric buses, among other things. We manufacture interior and exterior structural profiles for car body components as well as mechanisms for positioning and closing trailers, for example with voestalpine profilafroid/S.A.P. in France.

-

We develop and manufacture high-strength tubes and profiles together with our customers to meet their specific requirements. Thanks to sophisticated finishing options, the number of individual components is reduced for the fabricator.

-

We manufacture large outer skin parts made of sheet steel or aluminum for vans and commercial vehicles with tool sizes of one and a half to five meters on fully automated press lines. Our product range includes side panels, hoods, fenders and doors.

-

The assembly of steel components into large structural parts for vans and commercial vehicles is one of the special qualifications of our Dutch company voestalpine Automotive Components Bunschoten. Using joining technologies such as spot, projection and CO2welding, we complete entire component groups such as bumpers or floor panels in robotized, flexibly equipped assembly cells.

In Bunschoten, we also produce complex outer skin assemblies for vans and commercial vehicles. We can use a variety of joining technologies such as laser welding and soldering, clinching, riveting, gluing and roller hemming in robotized production cells, e.g. for the completion of hoods, fenders and doors.

For optimum support, we accompany our customers throughout the entire development cycle, including the prototype construction phase, and develop customized logistics solutions for the production period.

Safety cabins

The development and component production of safety cabs for forklifts, tractors, agricultural and construction machinery and special vehicles is one of our key areas of expertise. Group-wide synergies give our profiling specialists ongoing access to the latest material and technology developments.

-

Components used in the construction machinery, forklift truck and agricultural machinery industries must meet the highest safety requirements. This is especially true when the cabs used have to meet the requirements of roll-over tests. Our profile solutions are specially designed for this purpose, the so-called ROPS, the "Roll Over Protective Structure". From sophisticated cab/window profiles and various tubes and profiles for construction and agricultural machinery to components for safety cabs, our components meet the highest safety and load-bearing capacity requirements.

-

In addition to ROPS, this also applies to protective structures that protect drivers and equipment from falling objects, the "Falling Objects Protective Structure", or FOPS for short. We ensure that our high-frequency welded ROPS and FOPS tubes meet or exceed the highest strength and durability standards. With the help of eddy current testing, destructive and non-destructive welding tests, we ensure the reliability of our product quality.

Contact persons can be found at our sites in Europe, China and America, e.g. at voestalpine Sadef in Belgium, voestalpine Krems in Austria, voestalpine Meincol in Brazil or voestalpine Roll Forming Corporation in the USA.

The seamless hot-rolled profile tubes, which are now new to the voestalpine Tubulars portfolio, also offer outstanding quality and optimum product properties for this area of application.

Agricultural machinery, construction machinery, lifting equipment

Yellow Goods impress with their universal application capabilities. Manufacturers of agricultural machinery, construction machinery and lifting equipment rely on our materials and manufacturing solutions for the production of equipment, cranes, etc. This applies in particular to the use of our high-strength and ultra-high-strength steels in the production of heavy-duty construction and material handling machinery and agricultural equipment. We use reliable, innovative manufacturing technologies such as our roll forming solutions and the associated joining technologies, for example to create stable lifting structures.

With endurance® extreme, for example, we provide the optimum range of profiles for agricultural equipment subject to vibrations. High-strength steels as well as tube and profile solutions for booms allow cranes and other lifting equipment to achieve maximum performance with greatly reduced dead weight - thanks to lightweight construction technology. In the area of parts and components, our innovative materials facilitate functional integration. We offer an industry-leading portfolio of high-quality high-strength steels for cold, hot and roll forming as well as for tailored property parts.

In the mechanical engineering sector, the voestalpine Foundry Group has made a name for itself with the production of castings for special mechanical engineering applications. Our castings are used in areas such as special transportation, earthmoving, mining and special machine construction.

Our castingsare particularly in demand for large presses, rolling and forging machines, which weigh just a few kilograms to 200 tons and have special material properties.

Joining

Welding processes are the most frequently used joining techniques in the production of commercial vehicles. Welding consumables and solders from voestalpine BÖHLER Welding are used by manufacturers worldwide. We provide the commercial vehicle and yellow goods manufacturers and their suppliers with the optimum filler metal for every application.

Our welding equipment, tailored to the respective application, offers the perfect solutions for the industry, e.g. the TERRA 400 for lifting equipment - used in combination with ArcDrive and RapiDeep processes. Our diamondspark filler wire or solid wires such as Böhler X70-IG can be used for high-strength joints.

Wire rod for welding consumables used in gas-shielded and submerged arc welding is produced by our voestalpine Wire Rod Austria. The wire rod is manufactured in accordance with national and international standards.