We put together a comprehensive range of products for the food industry, including "Food & Beverage". Naturally, the high requirements of the industry are taken into account. Our delivery spectrum for Food & Beverage includes, among other things:

- High-performance materials for mills and knives;

- Profiles for pasture fences, fruit and vine trellises;

- Engineered products for food processing;

- Special steels for knives;

- Precision steel strapping for food packaging;

- Reinforcing wires for high-pressure pasteurization.

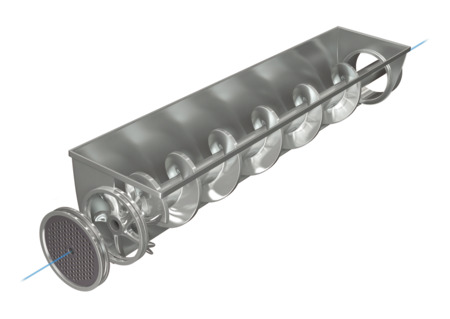

- Cutter bowls

From an economic point of view, the international food industry attaches great importance to safe, efficient production with minimal downtime. Our product ranges make a significant contribution to meeting this requirement. And as the world's leading manufacturer of high-performance materials, we know that product safety is of the utmost importance: wherever necessary, our products are specially tested and approved for the food industry.

Materials for the food industry

Food processing companies that pay particular attention to the corrosion resistance of their systems and equipment do not have to compromise on the wear resistance of the materials used. With our products, e.g. from the Uddeholm Stainless Concept, we offer solutions for the most demanding working materials. These steel grades are all certified by Normpack for the requirements of the food industry in accordance with EU legislation (1935/2004). They meet the requirements for materials that come into contact with food. They are used in components such as knives, rollers, screws, screw segments and cylinders for the extrusion of food and perforated plates for mincing meat.

We have the relevant steel grades certified in accordance with European Union legislation (1935/2004). This ensures that the materials are suitable for use in areas such as

- dry food,

- foods containing acid or alcohol or

- fatty foods

can be used. For example, acid-resistant steel from our voestalpine Böhler Edelstahl or Uddeholms AB production facilities is used for portioning units, such as those used for decorating desserts with fruit jellies and the like.

-

When designing steel brands for the food industry, we pay attention to their high resistance to wear. And to ensure that no elements from the alloys are transferred to the food.

Our steels withstand even the most demanding requirements, e.g. in sugar and ethanol production. Villares Metals, our Brazilian company in the High Performance Metals Division, offers stainless steels and special alloys for these applications.

-

When processing sugar cane, the efficiency of extracting the sugary juice depends directly on how wear-resistant the components in the sugar mills are. Our customers achieve decisive surface protection of the components through build-up welding. For example, the roller crushers in the sugar mill are "hardfaced" with rod electrodes from the voestalpine Böhler Welding Group. This serves to improve the juicing performance and maintain throughput by preventing the crushed sugar cane from slipping when it is drawn into the counter-rotating rollers. Other wear parts in the factory are also constantly protected with hard coatings from our UTP welding additives, such as the shredders, which have to cope with both the tough sugar cane and the sand that is introduced.

Our voestalpine Böhler Welding Group supplies the sugar cane industry with products for maintenance and repair, build-up welding and metal coating. These include UTP special cored wires and stick electrodes with alloys of complex carbides and with specific hardness.

Food production

From agricultural production to the preparation of food and beverages, the food industry can count on the safety and reliability of our products. Together with our customers, we develop the optimum variant for the respective applications as required.

We manufacture both primary products and engineered products from our high-quality materials for various knife applications, including heat treatment and finishing. In most cases, engineered products are the right answer to special challenges in the food industry. We design and manufacture them to measure from voestalpine premium materials in all the necessary production steps and supply them as ready-to-use, customized parts.

-

Blades for cutting food, especially a wide variety of meat and vegetable products, have become a highly specialized commodity. From steak knives to saws for frozen products, a wide range of cutting tools has been developed for the food industry. The primary material, which guarantees long-lasting sharpness and corrosion resistance, is supplied by voestalpine companies in Sweden and Austria.

Our solutions offer optimized processing properties, less product contamination and improved hygiene and durability. We manufacture knives for all types of industrial machines and for all major manufacturers of processing machines by customer agreement.

-

Food processors attach great importance to achieving a product appearance that appeals to consumers. In addition, hygienic processing that minimizes microbial contamination and safe working practices are important factors. We support the food industry in achieving these goals with our blades for meat, vegetables and bread.

With precision strip steels from voestalpine Precision Strip, our customers manufacture saw blades, knives and cutting blades with long-lasting sharpness, precise cutting geometry and a perfect surface. The precisely adjusted material parameters ensure that these cutting tools are the best choice for portioning and cutting

- fresh or frozen meat and fish

- Cold cuts, ham, bacon and cheese

- Bread and other baked goods

A good surface finish leads to a better appearance and color of the food, it also extends the shelf life of the product and leads to a reduction in food waste.

-

Whether for meat or meat substitutes - the voestalpine Foundry Group's cutter bowls are convincing in all areas. Our steel castings offer the perfect solution for every weight class. They are characterized by extreme durability and can withstand even the toughest conditions. With decades of know-how, we guarantee the highest precision and quality from casting to the finished product.

-

voestalpine Meat Grinding Kits for stuffing machines are made from our high-quality materials combined with an optimized PVD coating. This ready-to-use solution offers improved processing properties, less product contamination and improved hygiene and durability. At voestalpine High Performance Metals Denmark, for example, mincer sets are tailored to the specific needs of the producer: Particularly high-cutting knives and perforated disks, which are provided with a PVD coating by voestalpine eifeler. This gives the filling mass the optimum consistency and reduces the drying time of the raw sausages by around 10 percent. The higher efficiency lowers operating costs and reduces the effort required for resharpening the components.

-

As a ready-to-use solution, voestalpine film cutting knives offer improved processing properties and increased machine utilization, resulting in higher productivity for the machine operator. We supply the complete package, including horizontal and circular knives, fully heat-treated and finished.

-

Screening, cleaning and classifying crops is a responsible task in the supply chain. For this purpose, voestalpine BÖHLER Bleche supplies reliable and long-term usable sieve plates and trommels for pulses, grain, flour, etc.

-

We use our profiles to produce sustainable and durable structures for the global fruit and wine-growing industry.

-

The versatile FlexAgri Fruit system from our Belgian company voestalpine Sadef protects orchards from heavy hailstorms, downpours or frost. A roof structure supported by steel profiles provides optimum protection for the fruit trees and can also serve as a mounting structure for solar modules. A steel structure for many purposes.

-

We offer the leova® vineyard stakes from voestalpine Krems in various designs and lengths. We have the right combination of cross-section, length, claw, wire guide width and galvanization for every requirement. With leova® FRUCTUR, they can also be used in fruit growing. With leova® SMART, we are bringing our vine stakes into the digital age, offering the first real-time information and control system. It measures the microclimate, warns of frost, informs about precipitation and fungal diseases on the spot in the vineyard or orchard. The system is easy to install and can withstand the toughest demands.

-

Valeno® posts, manufactured by voestalpine Meincol in Brazil, are suitable for a wide range of agricultural applications. The adaptable design and specific holes of valeno® ensure that each plant receives the ideal support for healthy and productive growth. Profivi vine stakes come from voestalpine Profilafroid in France. Like its Brazilian sister, the system supports the sensitive vines in the vineyard or plants in the orchard.

-

Grinders have a particularly hard job to do when grinding for enjoyment. Pulverizing coffee beans, spices, etc. places extraordinary demands on the tools used. The risk of breakage on the grinder must be low, even with occasional stones in the ground material; at the same time, consistently sharp edges must ensure optimum results. In use: materials from voestalpine BÖHLER Edelstahl GmbH.

-

With steels for the food industry, voestalpine Böhler Edelstahl also ensures the variety of types of the popular pasta. Alloys tailored to the specific application are used as extrusion screws to press the dough through steel dies into the shape of spaghetti, penne or fusilli.

-

Freshwater and saltwater fish are finely skinned and filleted with sharp blades made of strip steel from voestalpine Precision Strip AB (Sweden). Their high quality ensures minimal waste and undisturbed enjoyment.

-

Well portioned poultry parts reach the customer. voestalpine High Performance Metals Colombia S.A. helps to cover the growing per capita consumption in Colombia and other South American countries with its knives. They are mainly used for shredding chicken and the like.

Hygiene and packaging

Food must be and remain free from dangerous germs. Pathogens and other contaminants make fish, meat, milk etc. inedible and pose health risks. In our diverse portfolio, we therefore provide the industry with effective products that contribute to the hygienic processing and storage of food and improve its shelf life.

-

Cooling food is a method of extending its shelf life that has been continuously improved for thousands of years. Millions of modern refrigeration systems in industry and households are operated with compressors. They compress the refrigerant in the cooling system in order to set the desired temperature level effectively and reliably. We produce valve flap steel for this purpose, a high-quality, metallurgically pure strip steel that we harden and anneal martensitically. This is because the valve flap of a compressor must open and close billions of times in its working life without showing any signs of fatigue or requiring maintenance.

-

For the food and beverage industry, it is essential that surfaces are hygienically clean during processing and that the stainless steel used reliably achieves its intended service life. After all, if the surfaces of machines, tanks or equipment are not treated properly at the end of production, corrosion can shorten their service life - but above all, there is then a risk of contamination of food or beverages.

Corrosion threatens both food safety and processing equipment. In some applications, it can be caused by highly corrosive disinfectants during cleaning or by the production environment itself. Fish processing plants, for example, are confronted with seawater and blood. Our voestalpine Böhler weldCare AB in Malmö, Sweden, offers concepts for cleaning and passivating surfaces to restore them to their original condition.

Our cleaning agents for stainless steel in the food industry have proven their worth in the French wine industry, for example, when cleaning steel tanks.

-

Fresh orange juice, even out of season, without additives or preservatives - we owe this offer to an innovative technology that also includes voestalpine products. In high-pressure pasteurization, fruit, juices or meat are exposed to an ambient pressure of approx. 6,000 bar in a water tank. In contrast to aromas and vitamins, unwanted harmful organisms cannot withstand this pressure. However, the natural appearance of the food remains largely unchanged. To enable the food industry to work with ultra-high pressures in pasteurization chambers, we supply reliable reinforcing wires: special profile wires such as those produced by voestalpine Wire Technology.

-

Industrial and consumer goods are only delivered with suitable packaging.

Folding cartons in particular offer protection for the product and ensure safe transportation. Large containers, banana boxes, pizza boxes, fast food packaging: In purely statistical terms, every third to fifth package for food or other goods worldwide is formed into its shape using products from our voestalpine Precision Strip. Sustainable paper and cardboard packaging is punched, cut and folded with Bohlerstrip cutting and punching lines.Packaging for potato chips, for example, may have been produced using film stretching machines with special guide tracks made from voestalpine Precision Strip steel strip. In the Colombian poultry industry boom, with a good 25% growth rate, special knives from our voestalpine HPM Colombia ensure the clean cutting of vacuum packaging for portioned poultry parts.