Hardly any other industrial sector is as multifaceted as mechanical and plant engineering. Whether tool or textile machines, conveyor or mining equipment, fittings or drive technology—with our materials and preliminary products, we supply key products for mechanical engineering. With the steels and profiles from our globally positioned profile forming locations, voestalpine is also a sought-after partner for challenging steel construction projects.

Our product range includes

- innovative materials and precise processing solutions for mechanical engineering as well as

- products for steel construction.

With alform®, we are once again proving our leading role in the production of lightweight materials for mechanical and steel construction. With this ultra-high-strength material, our customers achieve the optimal balance between lightness and stability; complex machines exhibit high load-bearing capacity with optimized weight savings: with significant weight savings due to lower material thicknesses with the same stability, with high load-bearing capacity due to excellent strength properties, and with the best processing characteristics, e.g., for welding and edging.

Mechanical engineering

Mechanical and plant engineering is one of the most important segments of modern industry. We supply these industries with innovative materials and precise processing solutions.

Materials for machines

Our wide range of products and services leaves virtually nothing to be desired in the mechanical engineering industry. From our own pig iron production to the final services provided in the voestalpine service centers, our employees accompany the steel products with their expertise. Our range of products and services includes:

-

When shafts, gears, and bolts need to be manufactured, our case-hardening steels come into play—medium-alloyed and unalloyed steels with a carbon content of up to 0.25%, usually fine-grained and with added sulfur.

-

Free-cutting steels are steels that we optimize for machining on automated machine tools by alloying them with elements such as sulfur: the chips break at the brittle inclusions.

-

Our cold-formed steels are aluminum-killed, medium-alloyed, and unalloyed steels, some with boron added. They are particularly suitable for the manufacture of bolts, nuts, screws, or materials for further mechanical processing.

-

We cut our hot-rolled flat steel to precisely meet our customers' requirements. Our product range extends from mild steels that meet the highest forming requirements to ultra-high-strength steels for the toughest applications.

-

voestalpine's roller bearing steels are used in roller bearings in all areas of mechanical engineering. The material, which is used as rolling elements in the form of rings and rollers, is alloyed mainly with chromium in addition to carbon. We achieve its hardness values of more than 60 HRC, its wear resistance, and its fatigue strength through hardening and tempering and a special steel purity.

-

Our cold work steels are primarily used in tools for non-cutting forming. We achieve their special performance parameters, such as hardness, wear resistance, and fatigue strength, by alloying with carbon and chromium, tungsten, molybdenum, vanadium, and manganese.

-

With alform®, we offer an ultra-high-strength material that allows for a potential reduction in material thickness of more than 70%. This voestalpine product is characterized by its excellent machinability, forming behavior, and outstanding toughness. In combination with our alform welding system, ultra-high-strength welded joints can also be achieved. With alform®, we offer an ultra-high-strength material that allows for a possible reduction in material thickness of more than 70%. This voestalpine product is characterized by its excellent machinability, formability, and outstanding toughness. In combination with our alform welding system, ultra-high-strength welded joints can also be achieved.

-

Our structural steels are used for a wide range of applications throughout mechanical engineering. These include heat-treatable steels and high-strength steels for lightweight construction, as well as case-hardening steels for gear manufacturing.

Our BÖHLER V723 VMR from voestalpine BÖHLER Edelstahl GmbH is used, for example, in long-term applications and in highly stressed components such as gears, screws, precision parts, and many more. The corrosion-resistant BÖHLER N664 is typically used for components in general mechanical engineering.

Profiles and pipes

Where mechanical engineering involves extreme stresses and high static loads, our strip steels and voestalpine's load-bearing roll-formed components and complete solutions prove their worth: in industrial and textile machinery, as well as in various plant components in industrial production machinery and power plants, as drive units, gearboxes, or motors. For this purpose, we supply, among other things:

-

-

-

Quickly available, ready for storage, and optimized in terms of dimensions, weight, and requirements according to customer specifications

-

The products of the profile and tube specialists in our Metal Forming Division tailor their products to the specific requirements of their customers in all aspects, whether technical, economic, or logistical—far beyond the standardized norm.

The expertise of our global suppliers of profiles and tubes is particularly valuable to the mechanical engineering industry when precision parts such as shafts, rollers, rings, dimensionally accurate profiles, etc. are required. For mechanical engineering, we supply solutions tailored to individual customer requirements, including high-strength steel grades, as well as complete solutions with ready-to-assemble components. We also adhere to the tightest tolerances on long profiles.

Our voestalpine Tubulars GmbH stands for diverse solutions in the seamless tube segment: Mechanical engineering, construction, and fastening tubes are adapted to the individual requirements of our customers. The tube and profile solutions from voestalpine Krems have been specially developed for the most challenging conditions. They are easy to process and guarantee significant weight savings—without compromising on safety and reliability. For special customer requirements, our roll forming company in the USA, voestalpine Roll Forming Corporation, offers customer-specific roll forming, bending, welding, and cutting of components, structural tubes, and assemblies in three states.

voestalpine Rotec GmbH manufactures precision steel tubes and profiles using a particularly resource-efficient cold drawing process. The products impress with their wide range of dimensions, maximum precision, and excellent mechanical properties. This makes them ideal for applications that require exact dimensional accuracy, specific surfaces, and sophisticated geometries. Further specialized services for the mechanical engineering and steel construction industries are offered by the companies of the Metal Forming Division in Brazil, China, Austria, Belgium, and the United Kingdom, among others.

Wire in mechanical engineering

Unique in this industry, we manufacture wires in integrated production across a continuous value chain—from ore to finished wire product from a single source. The products of our specialists at voestalpine Wire Technology thus offer the optimal conditions for further processing in the mechanical engineering industry:

- Best microstructural properties, high degree of purity, minimal segregation

- Highest surface quality

- State-of-the-art annealing facilities with optimal annealing cycles for the best material properties

- Quality control in well-equipped laboratories with a variety of in-line surface inspection technologies, such as eddy current testing or optical testing technologies.

Our product range includes:

-

We have optimized the properties of our roller bearing wires for the manufacture of ball, roller, tapered, and needle bearings. voestalpine Wire Technology guarantees the highest purity, uniformity, hardenability, best formability, and dimensional stability of its products.

-

Our flat and profile wires offer the best solutions for a wide range of applications. With cross-sectional dimensions ranging from approximately 2 mm² to approximately 200 mm², they meet the highest quality standards. The wide variety of profile types includes rectangular and trapezoidal profile wire, flat wire, square and half-round wire, as well as customer-specific shapes.

-

Our voestalpine Wire Rod Austria produces wire rod for welding consumables used in gas-shielded and submerged arc welding. Our wire rod is manufactured in accordance with national and international standards.

-

Our voestalpine Wire Germany and voestalpine Wire Italy plants produce drawn wire for machining on automated machine tools.

Heavy plate in mechanical engineering

When mechanical engineering requires exceptional strength and toughness, wear resistance, and durability, the products offered by our voestalpine Grobblech GmbH come into play. The product range includes, among other things:

-

Shell plates, bottoms, and cones, both carbon steel and roll-plated. We are the only supplier worldwide that can deliver shell plates, bottoms, and cones made of carbon steel and in a plated design from a single source. For bottoms and pressed parts made of carbon steel, we use structural steels and fine-grained structural steels as well as pressure vessel steels.

-

Our heat-resistant pressure vessel steels can withstand even the highest temperatures. They are particularly suitable for hot pressure vessels. Obtaining all components, such as shell plates, bottoms, and cones, from a single source means optimal processing quality for our customers, as the base materials are perfectly matched in our factory. The wide range of grades and steels allows for a broad range of applications.

To reduce the wall thicknesses of very thick-walled pressure vessels, we offer high-strength CrMo and CrMoV steels, e.g., for liquid gas tankers. -

Our cold-resistant nickel sheets are ideal for use at extremely low temperatures. In the field of liquid natural gas storage, ASTM A 645 Gr B offers equivalent material properties to traditional 9% nickel steel, but with approximately 30% less nickel content. This also leads to a significant reduction in costs.

-

The high-strength heavy plates from voestalpine enable a minimum yield strength of 700 MPa as fine-grained steels and up to 1100 MPa as ultra-high-strength special grades.

-

Our general structural steels are used in a wide range of applications in steel construction, bridge construction, hall construction, vehicle construction, and wind towers.

-

Our thermomechanically rolled fine-grain steels—available in normal-strength and high-strength versions—offer minimum yield strengths ranging from 355 to 550 MPa. They are characterized by excellent toughness and outstanding welding and forming properties.

-

Our durostat® steels are online-hardened carbon steels with particularly high wear resistance and excellent processing properties. As roll-clad multi-layer sheets, altrix® steels offer exceptional resistance to abrasion – for maximum service life even under extreme conditions.

Foundry products for machines

For the mechanical engineering sector, e.g., for special applications in mining, for large presses, special transport, rolling and forging machines, we supply castings weighing from just a few kilograms to 200 tons per piece. The special properties for these applications are provided by the foundries of our voestalpine Foundry Group.

Our portfolio of castings for mechanical engineering includes:

- Stands and anvils for forging machines

- Hammer bearings for counter-strike hammers

- Roll stands, inserts, and other castings for rolling mills

- Steel castings for general mechanical engineering applications

The voestalpine foundries offer a wide range of special services that support manufacturers in the production of particularly challenging machines and machine components.

-

For mechanical engineering, we supply steel and ductile iron castings ready for installation in a wide range of strengths and toughnesses. Special steel grades are available for special applications.

-

For our customers who need castings extremely quickly, we offer a special service called fastlane®, which guarantees significantly shorter and reliable delivery times. We have eliminated the long lead times traditionally associated with casting production thanks to innovative 3D sand printing technology, robotic welding, and many other optimizations in the production process.

-

The lead-free zinc-based alloy alzen® 305 was developed by voestalpine. It is particularly suitable for use as a bearing material and also offers further possibilities and advantages. alzen® alloys are in demand in mechanical engineering as well as in other branches of industry. Their applications range from bushings, pipes, and sheets to plain bearings, worm gears, and roller bearing cages.

-

Our voestalpine Camtec GmbH supplies sliding elements and bushings ready for installation in a wide variety of shapes and also in different bronze materials. The range extends from sliding elements, bushings, and bearing segments to hydraulic components such as sealing rings and other customer-specific special parts.

Services for mechanical engineering

We support our innovative mechanical engineering offerings with an extensive service network. Both the Steel & Service Center of the Steel Division and the service network of the High Performance Metals Division are available worldwide to meet the needs of our customers.

Services include, among others:

-

We manufacture high-quality sheets to the highest customer requirements on state-of-the-art slitting lines. The tightest tolerances are a matter of course.

-

Our voestalpine High Performance Metals division offers machining services through its global sales network to reduce lead times for our customers. The most important services offered are: 6-sided machining of plates, gun drilling for cooling channels, contour machining, roll forming tools, and contour machining of open-die forgings. The services may vary from one location to another.

-

voestalpine High Performance Metals GmbH manufactures shafts, columns, spindles, and similar components according to customer specifications, including heat treatment.

-

It's just a few micrometers that make all the difference. The ultra-thin coatings applied by our voestalpine eifeler Group make a significant contribution to greater hardness and less wear. Our service portfolio includes PVD and CVD coatings, including the necessary heat treatment.

steel construction

The advantage of steel construction lies in the ability to work with relatively few, simple basic elements, for example to bridge large spans. We supply the steel construction industry with the necessary steel elements for these services. Our materials offer special performance parameters that support lightweight construction, for example with lower material thicknesses.

The lower weight of steel frames and beams saves costs and reduces emissions. With our hot-dip galvanized steel strip from voestalpine Stahl GmbH, we also offer excellent corrosion protection, which further strengthens the sustainability concept when using steel.

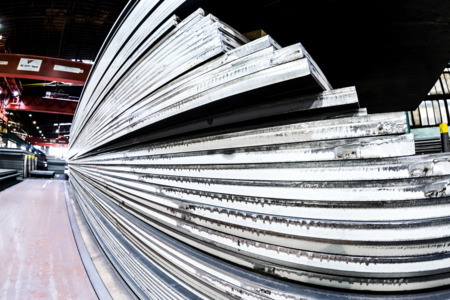

Heavy plate in steel construction

Heavy plates are heavyweights in steel construction. With a thickness of 3 mm and more, they ensure stability and lightness in structures. We bridge this apparent contradiction with heavy plates made of high-strength steels, which allow for less material to be used while maintaining the same or even higher performance. The products of our voestalpine Grobblech GmbH are primarily used in extreme conditions. Exceptional strength and toughness, wear resistance, and durability are the focus of our product range:

-

Our tool and free-cutting steels are mainly heat-treated after final processing, which gives them their final properties.

-

General-purpose voestalpine structural steels are used in a wide range of applications in steel, bridge, and hall construction, as well as in wind towers.

-

These steel grades are used for cruise ship cabin superstructures. Particularly thin sheets are used in large widths for this purpose—they offer the best processing properties such as flatness and weldability. High-strength thermomechanically rolled shipbuilding plates, on the other hand, are used in the offshore sector. They are used for deck superstructures on platforms or for special ships in the oil and gas industry.

-

Our thermomechanically rolled fine-grain structural steels include alform® steels. Their excellent weldability, toughness, and cold formability make them particularly versatile. They offer

significant weight savings

high load-bearing capacity, and

excellent processing characteristics. -

When heavy plates require special protection against weathering, we use weather-resistant steels: by alloying small amounts of phosphorus, copper, nickel, chromium, or molybdenum, we achieve the formation of a protective layer on the steel for outdoor use. Weather-resistant structural steels thus offer cost advantages, as no anti-corrosion coating or maintenance of the protective coating is required.

-

The high-strength heavy plates from voestalpine are fine-grained steels with a minimum yield strength of 700 MPa. The ultra-high-strength special grades even reach up to 1100 MPa.

-

Our voestalpine High Performance Metals GmbH produces chemically resistant special materials for steel construction. They prove their reliability over a long period of time under corrosive atmospheric, chemical, or extreme heat conditions.

Solutions for steel construction technology

Like all large-scale construction projects, steel construction poses logistical challenges, such as lifting heavy loads. As construction projects grow, so does the size of the construction machinery required. To keep their weight as low as possible, we offer solutions made from ultra-high-strength steels – for heavy-duty lifting technology, railcars, articulated and mobile cranes, concrete pumps, and much more.

The lightweight construction concept saves real costs thanks to the lower weight of construction equipment and ensures lower emissions. With our alform® steels, we provide the industry with a wide range of high-strength and ultra-high-strength materials for the construction of cranes and other lifting and transport technology.

For the transport of construction materials, our customers use equipment and transport vehicles that utilize our durostat® from voestalpine Stahl GmbH, a particularly wear-resistant material. With its extraordinary hardness and toughness, this steel has properties that are particularly sought after in this construction segment. We give it these properties through a special cooling treatment: when the steel comes out of the rolling mill, it is cooled to room temperature in a matter of seconds. This gives it a particularly strong structure, from the surface to the core of the material.

Profile forming in steel construction

Profiles with a wide variety of cross-sections and thicknesses also demonstrate their strengths in steel construction. For example, hollow profiles with their comparatively low weight and bending resistance that is the same on all sides are ideal for use as structural elements. Our Profilform companies in Asia, Europe, North America, and South America supply a wide range of corresponding products. High-quality tube solutions are also manufactured by voestalpine Tubulars GmbH in Austria. We enable the effective use of profiles in steel construction with, among other things,

- solutions tailored to individual customer requirements,

- complete solutions with ready-to-assemble components,

- the use of high-strength steel grades, and

- the tightest tolerances on long profiles.

Wherever high static loads are involved, our strip steels as well as our load-bearing roll-formed components and complete solutions prove their worth.

Joining concepts

Our high level of expertise is also in demand when it comes to joining. This is because the crane and lifting industry has to handle ever-increasing loads reliably and safely. At the same time, there is a trend toward reducing the weight of cranes, especially in mobile crane and lifting solutions. With our welding expertise, we meet the demand for high quality and consistent mechanical properties in combination with high production rates. We support the increasing use of fine-grained, high-strength, and ultra-high-strength steels with solutions that fully meet these requirements: welding equipment, welding consumables, and much more.

voestalpine materials for steel construction always have corresponding welding concepts. These include the alform® welding system from voestalpine BÖHLER Welding and voestalpine Steel Division. This joint development is the world's first coordinated system of steel and welding consumables. It enables the material potential to be exploited to an unprecedented degree.